Installing Hybrid Balustrade Posts: What is the difference between installing my posts above or below the finished floor level?

Glass Balustrades | Juliet Balconies | Galleries | Articles | Case Studies

This article is structured in a way that intends to simplify the engineering principles that are employed to make our unique Hybrid® Balustrade system possible. We have invented a system that can have wide runs of glass that require no, or in some cases very few, vertical posts, which provides almost uninterrupted views at a fraction of the cost of structural frameless glass.

Once we have explained the innovative engineering behind how this is possible, we can then answer the title question ‘What is the difference between installing my posts above or below the finished floor level?’

Before you decide which method is best to install your posts, it is vital that you understand why posts are introduced to the Hybrid® system in the first place. To do this, we will address each question topic listed below and explain the answers regarding posts. When we have shared this knowledge, we will proceed to describe the differences between installing your posts above or below the finished floor level, and you will have the chance to evaluate which option is most suitable for you.

-

What are ‘Points of Support’?

-

What is the maximum span width for Hybrid® Balustrades without posts?

-

When are posts introduced to the Hybrid® system?

-

How do the posts work in the Hybrid® system?

-

What is the maximum span width for Hybrid® Balustrades with posts?

Stunning sea view from a Hybrid® Orbit Balustrade

Stunning sea view from a Hybrid® Orbit Balustrade

What are ‘Points of Support’?

When we talk about ‘points of support,’ it is important to understand the defining design feature of the Hybrid® Balustrade system, which is the handrail profile. Our precision-engineered handrail encases an invisible brace that provides the leading structural strength to the balustrade. The system utilises the strength of the handrail to achieve wide spans without needing vertical posts.

The spans spoken about here are the distances between where the handrail is connected and fixed to a supporting structure, i.e., fixed to a wall. The location of where the handrail is fixed is referred to in the industry as a ‘point of support.’ We also consider where two pieces of profile mechanically join at a 90° corner as a ‘point of support’ - but this is only applicable if the length of the handrail spans at least one metre on each side of the 90° corner.

The Hybrid® system integrates the strength of the handrail profiles, glass and ‘points of support’ to take the structural load. This unique design allows the balustrade to span large widths between ‘points of supports’ without relying on vertical posts or structural glass.

What is the maximum span width for Hybrid® Balustrades without posts?

As you know, we have two proprietary Hybrid® Balustrade systems to choose from, our Hybrid® Orbit and Hybrid® Aerofoil. Each balustrade is greatly admired for their remarkable ability to have a post-less system. A post-less system is attainable since each Hybrid® system has its own maximum handrail spans that can be achieved between ‘points of support’ before needing to add in supporting vertical posts. The different size spans are detailed below:

|

Max Span for a Handrail Run Without Posts |

Examples |

|

|

|

|

|

|

Here comes the engineering bit… The maximum spans explained above are achievable because the ‘points of support’ and handrail profile have been meticulously designed to work in unison to resist a structural load of 0.74 kilonewtons (kN) for every one metre length. Talking in plain terms, this means that the balustrade can withstand a series of people, each weighing 74kg resting their full weight against the handrail profile, one metre apart from each other.

When are posts introduced to the Hybrid® system?

There is a limit to the strength of the handrail, and vertical posts need to be added to the system when the handrail alone cannot withstand the structural load mentioned above – 0.74 kilonewtons (kN) for every one metre length. The handrail’s resistance to this load is compromised when either of these two situations occurs:

1. When the length of the Hybrid® handrail run surpasses the maximum allowable span without posts

2. When the handrail cannot be fixed firmly and securely into the structure or wall at both ends of the balustrade run

When either of these two scenarios occurs, vertical posts are introduced into the Hybrid® system for additional support.

How do the posts work in the Hybrid® system?

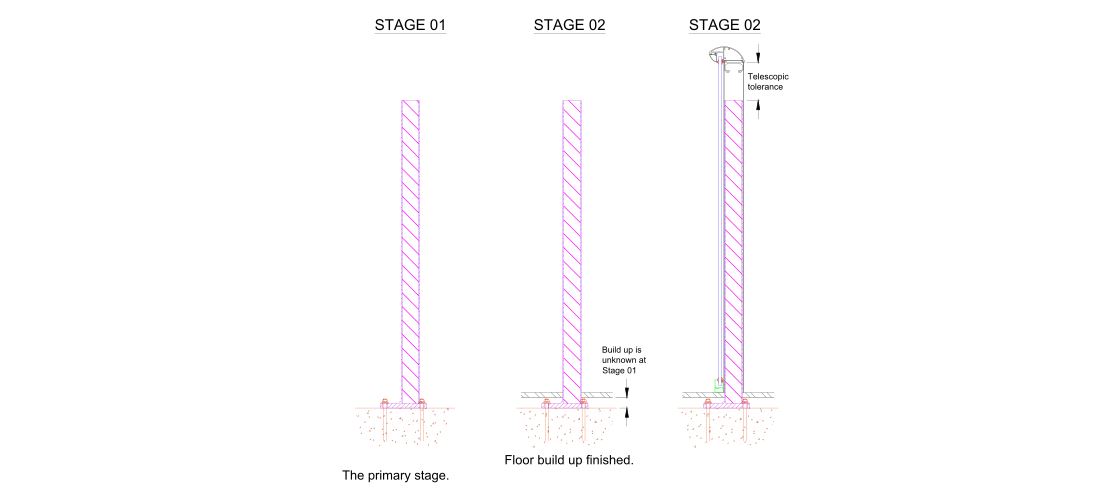

Our signature supporting posts are comprised of a two-part system; the first part is galvanised steel primary post, and the second part is an anodised aluminium cover post.

We use steel for our primary posts since it is three times stronger than aluminium. The steel posts have been coated in a layer of zinc to reinforce the posts further so that they can withstand high levels of mechanical stress. The protective zinc coating also fortifies the post’s resistance to rust and corrosion, even in coastal locations. The primary posts have a wide base plate that needs fixing to a structural surface - like how the handrail needs to be fixed into a structural wall. Fixing a primary base plate to a structural surface is the mechanism that now gives the balustrade its strength and ability to resist structural loads.

We promise you that you will never know that the structural steel post is even there once we bring the secondary post into the equation. The secondary post is a sleek cover that slides over and envelops the primary posts to conceal the unpolished steel. Each post is fabricated with anodised aluminium and is coloured in the same finish you have chosen for the rest of your balustrade, creating a flawless appearance that makes you forget the primary posts even existed. The matching anodised handrail is fixed on top of the covered primary post.

Our post’s impressive durability and style are desirable, but their telescopic feature makes our posts outstanding. This telescopic feature has been developed to fit post base plates above and below the finished floor level. This is made possible because the telescopic feature means that your cover post will be able to tolerate adjustments to the floor height.

Diagram outlining the telescopic post’s tolerances

Let me explain the telescopic feature further… Imagine that you want to fix your posts to a structural floor early in the installation process, but you don’t yet know what the height of the finished floor level will be. This situation has the potential of being a bit problematic since all external balustrades must meet a minimum height requirement of 1100mm. Still, you’d be pleased to know that the telescopic feature makes the early installation of the primary posts possible. The telescopic cover post can encase the exposed primary post once the uppermost surface floor has been laid. The telescopic feature will tolerate the space between the base plate and the finished floor level. The telescopic tolerance will ensure that when the handrail is fitted on top of the posts, the balustrade will achieve the 1100mm height requirement set by the British Building Standards.

What is the maximum span width for Hybrid® Balustrades with posts?

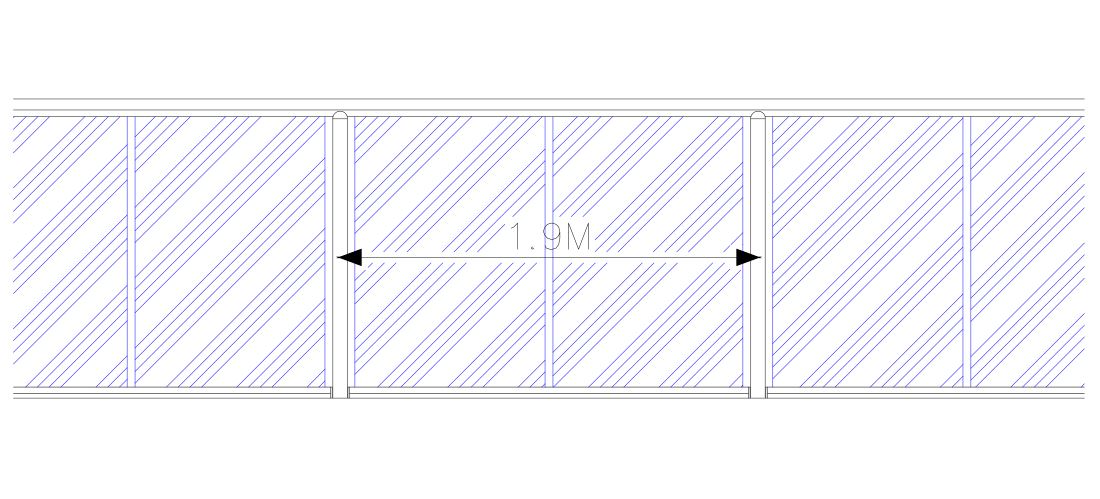

When posts are introduced into the Hybrid® systems, the maximum span between posts is smaller when compared to the maximum span of the handrail between ‘points of support.’

This is because the maximum span between posts is now determined by the strength of the posts, instead of the handrail and ‘point of support’, and more posts are required to achieve the same result and ensure that the system remains secured and anchored whilst under load.

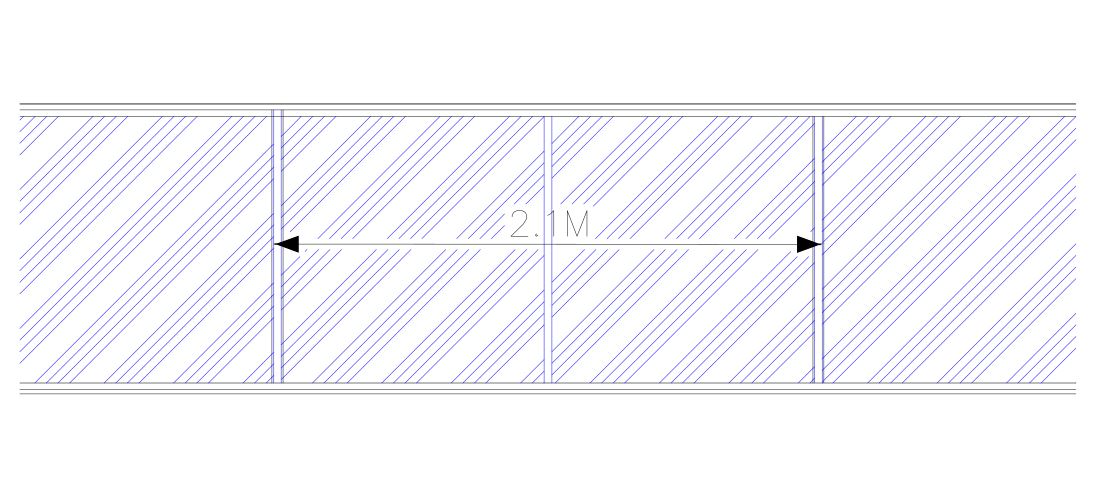

Below are the maximum post spacings for Hybrid® Orbit and Aerofoil systems:

|

Hybrid® Orbit maximum spacing between posts = 1900mm |

|

Hybrid® Aerofoil maximum spacing between posts = 2100mm |

|

|

| Hybrid® Aerofoil maximum spacing between posts | Hybrid® Orbit maximum spacing between posts |

What is the difference between installing my posts above or below the finished floor level?

We trust that the body of the article has explained when and why posts are introduced to the system and their importance to the system’s structural integrity. Now we can move on and describe the difference between installing the posts above or below the finished floor level by outlining the things to consider for each method, giving you the chance to prepare for possible eventualities and evaluate which option is most suitable for you. Each option is uncomplicated and achieves an exceptional outcome that will last for many years to come.

Things to consider when installing below finished floor level…

-

Install primary post early

To assist in early install preparations, it is possible to get your primary posts delivered to the site before the rest of your balustrade system and fix your primary post base plates to a structural surface. The exposed steel base plates can later be covered by building the ground and laying your finished floor level on top. The primary posts can be encased with our anodised cover posts, and the remaining system can be fitted from above the finished floor level. The telescopic feature is what allows the glass balustrade to have the base plates fixed to the structural floor, whilst the rest of the balcony system is fitted above the finished floor surface. The telescopic feature means that the height of your uppermost floor does not need to be known at the point of installation as the telescopic feature can tolerate for adjustments in the floor height. This option achieves an aesthetically pleasing, barely-there appearance where you can only see the vertical element of the post without any base plates or mechanical fixings on display.

.jpg.jpg)

Hybrid® Aerofoil Balustrade with base plates fitted below the finished floor level

-

Waterproof balcony

When installing your posts, you can seal and waterproof them around the base plates and below the balcony with ease. Please consult a waterproofing expert or a roofing contractor to decide and choose which waterproofing method is pertinent to your particular situation.

-

Strong structural fix

If you already have your final surface, such as decking, tiling or screed laid but you cannot get a structural fix from the finished floor level, you can remove or excavate the surface layer to get to the structural floor beneath. The posts can then be fixed below the decking, tile, or screed into an unyielding structural surface similar to steel or concrete. The disturbed floor will need to be repaired and sealed before the remaining system elements can be slotted over the primary posts and fitted above the surface floor.

Click here to watch a video of How to Install a Hybrid® Aerofoil below the finished floor level.

Hybrid® Orbit Balustrade with base plates fitted below the finished floor level

Things to consider when installing above the finished floor level…

-

Install a balcony after a project is finished

Fitting the post base plate above ground gives you the flexibility to add a balcony to your home at any time, even after your construction project is finished, or if you were unable to fit the base plates beneath the surface level. This method isn’t intrusive to your home since it doesn’t require additional ground reconstruction work and can simply be added above a finished floor level if a robust structural fixing is available.

-

Visible base plates

The post’s base plates are visible, but the raw base plate will be covered with an anodised aluminium base plate cover fabricated in the same finish you have chosen for the rest of your balustrade. When paired with the vertical cover post, the decorative base plate cover delivers a stylistic pillar effect, creating a prominent channel that helps to separate between different living areas. Post cover plates are currently only available in Royal Chrome and Silver anodised.

Hybrid® Aerofoil Balustrade with base plates fitted above the finished floor level

-

Ensure structural fix can be made from the surface floor

Have your site surveyed and get a trained professional to assess whether you can achieve a structural fix from the surface floor, ensuring that the floor isn’t soft or won’t compress under load. The fixings you use need to withstand loading pressure and should meet the fixings requirements that are outlined in our structural calculations. Attaching a balustrade to a substrate that is less strong than the balustrade itself or securing a balustrade with inappropriate fixings will result in damaging your property when the balustrade is subjected to heavy loads.

-

Reconstruct any damaged waterproofing after installation

This method could perforate the pre-existing waterproofing beneath the finished floor level during installation, leaving the structure vulnerable to water damage. If this occurs, consult a waterproofing expert or a roofing contractor on how best to reconstruct and repair any waterproofing that has been punctured during the installation – if the area is left unsealed and untreated, it could lead to water ingression damage.

Click here to watch a video of How to Install a Hybrid® Aerofoil above the finished floor level.

Hybrid® Orbit Balustrade with base plates fitted above the finished floor level