Glazing a Glass Balustrade safely

Glass Balustrades | Juliet Balconies | Galleries | Articles | Case Studies

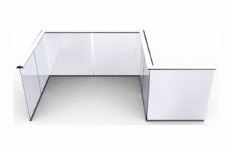

To price your balustrade requirement first choose the shape most similar to yours

Glazing beads

Both Hybrid® Orbit (previously known as Balcony 1 System) and Hybrid® Aerofoil (previously known as Balcony 2 System) balustrade systems utilise glazing beads. Glazing beads are parts of profiles that secure the glass in place. These glazing beads are a separate profile engineered and designed to fit perfectly into either the handrail or the bottom rail.

The procedure involves first fixing the bottom and top rails, and only after that, glazing the glass into the system. The recommended approach is to initially use small bits of glazing beads, off cuts of around 50mm to 100mm wide, and then position the glass in place. These small glazing bead parts can secure the

Positioning and lining up the glass

We supply glazing spacers or packers made of plastic, available in different thicknesses ranging from one to five mm. Once you have temporarily secured the glass with the small glazing bead parts, you can easily access and align the position of the glasses. Achieving equal gaps between panels and ensuring their vertical alignment is now straightforward.

Having access to the bottom of the glass allows you to use the plastic packers to slightly raise or lower one side. Access to the top of the glass means you can place packers on the top, providing a comfortable resting place for the handrail.

This flexibility in installation is tremendous because you don’t need everything to be perfect the first time you put in the glass. Place all the glasses in, secure them with temporary glazing beads, and then align all the glass lines and positions until you’re satisfied. At that point, everything is ready for bonding.

Bonding the glass to the system

An important part of the installation and one that turns the whole system into a strong rigid unit is the bonding, or siliconing stage. Still having access to the top and bottom of the glass, In this stage you bond the glass using silicone to the rails, both top and bottom.

A continuous bead of silicone is applied which when dry will glue the handrail to the top of the glass and a continuous bead under the glass which when dry will hold the bottom rail and the glass. This once it’s dried will hold all the glasses perfectly in position. They will no longer be able to move left or right, they will be glued all along to the bottom rail and top rail.

.jpg)

Replacing the long glazing beads

After the silicone has dried, you can seamlessly replace the long glazing beads – the complete glazing bead. This comprehensive bead, equipped with rubber, conceals all the silicone, both at the top and bottom lines of the installed glass.

The access and utilization of glazing beads play a pivotal role in the flexibility and ease of our system's installation. In contrast to other systems, where precise alignment and straightness are crucial, and the glass fitting must meet perfection, our approach differs.

With our systems, we proactively order all the glass and the system in advance. Everything is supplied, providing ample tolerance in the system for easy installation and a high degree of flexibility in dimensions and sizes.

Gaps between the Glass Panels

We typically supply glass panels with a 30mm gap between them. This 30mm gap not only serves various essential purposes but also allows for adaptability in overall sizes. In situations where the balustrade has been altered, either shortened or extended, the flexibility in the glass allows you to expand the gap from 30mm to 35mm or adjust it accordingly. This showcases the ample flexibility embedded in our system.

Even if the floor isn't perfectly level or has a slope, our glasses can accommodate it. By ordering glasses slightly shaped at the bottom, any imperfections due to the floor's levelness become inconspicuous. The installation appears straight, with all tolerances considered in the bottom rail and the glass distances. This stands as another key feature highlighting the flexibility of our systems.

.jpg)

Wind loads, vibration and other factors.

The combination of our robust glazing beads and the bonding process forms a system that is both rigid and flexible, capable of withstanding wind pressure, vibrations, and building movements. In a recent harsh winter storm, one of our customers was ecstatic about their balustrades standing strong against gale force winds. One customer even mentioned a remarkable 112 mph gale in their area.

The strategic use of silicone at the top and bottom adds essential rigid flexibility to the system, ensuring that the glass remains intact and the components stay within their designed stress levels, even under challenging conditions.

Glazing beads elements