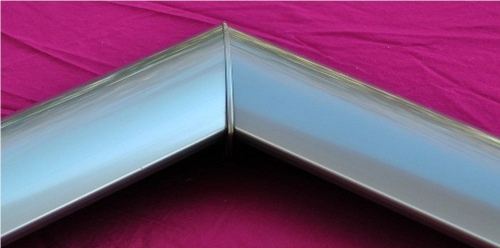

Glass Balcony Corners and Mitre Protection Plates

Glass Balustrades | Juliet Balconies | Galleries | Articles | Case Studies

Handrail joints and corners of balustrades

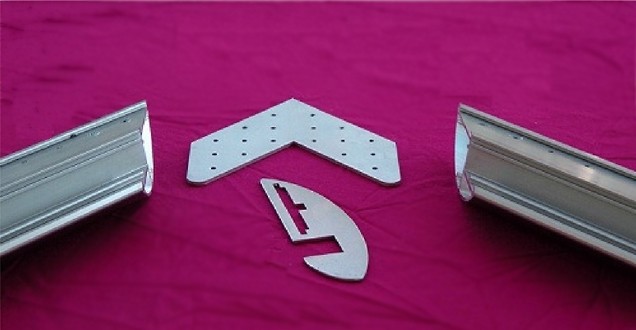

The corners are a very important element of our balustrade system and it is important to understand how they are connected. The end result looks so neat and nice that we are often asked if the corners and joins are actually welded.

Corners are not welded; they are mechanically fixed using special corner joining plates that slot into the handrail ends and get screwed together. Both sides of the corner joint are mechanically fixed on our system. This mechanical fixing is a very strong fixing and is relied upon to be part of the strength of the handrail.

Avoiding sharp edges

We’ve introduced a very nice feature to our system that gives that finishing touch to the system. We call these “Mitre Protection Plates” (MPPs).

These MPPs perform two important actions.

a) They protect the hands of people using the balcony from being cut on the sharp edges of the mitres.

b) They give tolerance to the mitre joint.

The mitre is defined as the “cut” profile at an angle which the handrail has. So if for instance you have a handrail that is required to go around a 90 degree corner, it is cut on one side at 45 degrees and on the mirror side at 45 degrees. This cut is called a “mitre cut”.

The MPPs have been designed to complement the system. As the angle changes the plate’s shape is different and so these MPPs are stocked in an array of angles to suit.

How do they work?

The MPPs protect the corner by creating a plate which has the contour of the shape of the mitre with an addition of circa two millimetres. The edges of the plates are rounded and polished so that when your hand is run along them thay have a smooth contour.

- It protects the corner

- It looks very nice because it looks like a weld when it’s properly joined and

- It performs another important action, it gives that little bit more tolerance in the joint.

Without that mitre protection plate, the joint, even if a few tenths of a millimetre off may not look very nice. You might see the aluminium contour; you might have it slightly twisted or just not perfectly joined. Or because one run is not exactly horizontal and so forth that creates a problem. But with the MPPs it adds that required tolerance in the joint.

These mitre protection plates are meant to help with giving that little bit more tolerance on the mitre joint.

The Royal chrome finish

Not only do they protect the hands from being cut, they are also very aesthetic and in a very nice finish. The mitre protection plates are always made and supplied in our proprietary Royal chrome anodise finish. This is regardless of the colour of the balcony handrail.

Creating a very nice joint

On curved balustrade handrails, that are made from more than one section of profile, we use a mitre protection plate on a straight joints. So if we have a long curve made up of several parts we will employ a flat mitre protection plate on the joints of straight (180 degrees).

When you’re joining a curve to a curve one might be just a little bit more distorted than the other. One handrail might be a little bit more twisted than the other and you may have a millimetre difference. The mitre protection plate eliminates that and creates a very nice joint between the two and from experience it stops all the problems.