Balconies and patio doors with self cleaning glass

Types of Self Cleaning Glass | Our Glass Solution | FAQ's | BalcoNano DIY Self Application Sachets

We now offer DOUBLE SIDED Self clean glass coating on our balcony glass panels and curved door panels!

Self cleaning glass balconies and self cleaning glass on patio doors and glass windows are now available.

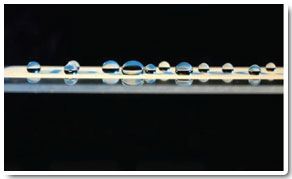

On our balcony systems we can now supply our glass, usually 10mm toughened glass, with the new patented hydrophobic protective coating. Glass balustrades now with this coating will remain cleaner for longer and will required a lot less cleaning. Maintenance will be reduced by at least 50% and can be even up to 90%.

Cleaning the glass requires just a cloth and some water, no chemicals or detergents and the glass is again as new. No chlorine, chloride or bleaches to damage your skin and the environment. We can compare this protective coating very much to the way Teflon ® protects your frying pan, it is not that your frying pan does not need cleaning if it has Teflon, it’s just that less dirt and grime will stick to it and it will be much easier to clean. The coating will protect the glass from dirt and grime and this will wash off easily but it will require to be cleaned. Same as you rinse off the frying pan when you have finished using it.

As the coating is applied in a CVD chamber so that both sides of the glass get coated and thus you enjoy the benefit of the self cleaning coating on the inside of the balcony as well as on the outside.

On our curved sliding doors the double glazing can also be applied with this coating. The application on curved glass is done after the glass has been insulated and the whole unit is placed into the chamber for the vapour treatment. Again this gives all the benefits of the self clean coating to this fantastic product both on the inside and the outside.

Our Technology

So how is this “self clean” coating applied?

Using a licensed and patented technology the unique CVD chamber was constructed to the manufacturers spec. This is an award winning technology that used a chemical vapour deposition process. The application can be made to any silica based materials like ceramic, glass, porcelain and granite.

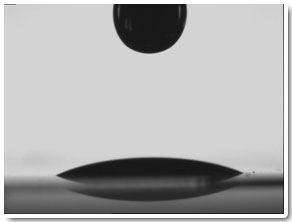

This is a two stage process and the chemical vapour reacts with the moisture and silica on the surface of the substrate.

Stage 1: The chemical reaction from this stage allows a silicone protective film to "grow" from below the surface of the material being treated. The molecules of this film are cross linked and branched basically meaning they hold on to each other like a web and so are very strongly connected to the surface.

Stage 2: This stage "caps" the molecule chains and stabilizes the film so it is neutral and inert to the environment and other materials. This guarantees the longevity of the coating and the strength and resistance to scratching and impact.

The reaction time of the vapour in each stage is almost instantaneous, under two second, but the whole process in the chamber takes usually about two hours.

Nanotechnology

Why is this technology considered Nanotechnology ?

The nanoscale is about a thousand times smaller than micro that is, about 1/80,000 of the diameter of a human hair. Approximately 3 to 6 atoms can fit inside of a nanometer, depending on the atom. The prefix nano means ten to the minus ninth power, or one billionth. Nanoscale technologies are the development and use of devices that have a size of only a few nanometers.

Nanotechnology is a technology based on the manipulation of individual atoms and molecules to build structures to complex, atomic specifications.

While many definitions for nanotechnology exist, this application concurs with the National Nanotechnology Initiative (1) definition, which denominates "nanotechnology"; only if it involves all of the following:

- Research and technology development at the atomic, molecular or macromolecular levels, in the length scale of approximately 1 - 100 nanometer range.

- Creating and using structures, devices and systems that have novel properties and functions because of their small and/or intermediate size.

- Ability to control or manipulate on the atomic scale.

This self clean coating, a patented process, works at nanoscale levels, approximately 30 nanometers. The change of the molecular composition of the silica-based surface created by this chemistry and bonding nanoparticles, along with the cross-linking, branching, and final "capping", enables the full efficiency of the coating process at an atomic scale.

Nanotechnology has the potential to profoundly change our economy and to improve our standard of living, in a manner not unlike the impact made by advances over the past two decades by information technology.

Numerous products featuring the unique properties of nanoscale materials are available to consumers and industry today. Nanotechnology is used in electronic, magnetic and optoelectronic, biomedical, pharmaceutical, cosmetic, energy, chemical-mechanical polishing, magnetic recording tapes, sunscreens, automotive catalyst supports, biolabeling, electro conductive coatings and optical fibres.

Although the main applications of Nanotechnology have been developed in the computer and electronics fields, some other current uses that are already in the marketplace include:

- Stain-free clothing

- Coatings for easier cleaning of glass surfaces

- Bumpers and catalytic converters on cars

- Protective and glare-reducing coatings for eyeglasses and cars

- Sunscreens and cosmetics

- Longer-lasting tennis balls

- Light-weight, stronger tennis racquets

- Ink

- Water filtration

- Step assists on vans

So in summing up the self cleaning glass coating provided through this technology is truly a ground breaking achievement.

The chamber technology now allows this self cleaning coating to be abundant, viable and available. It is our aim to make this a standard supply as an integral part offa our glass balcony and patio door products and we aim to make it an added benefit to the end user.

Note to end users: The name self cleaning can be misleading, as all types of self cleaning glass will actually require cleaning and maintenance. Reference to these types of glasses and glass coatings in the market is as “self cleaning”. It is important that the end user does make themselves familiar with what they are buying or receiving. We have endeavoured to supply the end user with real and factual information on the products we offer in a true effort to create true expectations from the product/s.